-

CROSBY: G209A SCREW PIN SHACKLE

2018-01-15 11:03:15FEATURES

• Capacities 2 thru 21 metric tons. Meets performance requirements of Grade

8 shackles

• Forged Alloy Steel – Quenched and Tempered, with alloy pins

• Working Load Limit permanently shown on every shackle

• Hot Dip Galvanized

• Shackles can be furnished proof tested with certificates to designated

standards

• Meets or exceeds all requirements of ASME B30.26 including identification,

ductility, design factor, proof load and temperature requirements. Import

antly, these shackles meet other critical performance requirements including

impact properties and material traceability, not addressed by ASME B30.26

Screw pin anchor shackles meet the performance requirements of

Federal Specification RR-C-271F Type IVA, Grade B, Class 2, except

for those provisions required of the contractor. For additional

information.Nominal

Size

(in.)

WLL

(T*)

STOCK NO.

UPC NO.

WEIGHT

(LBS.)

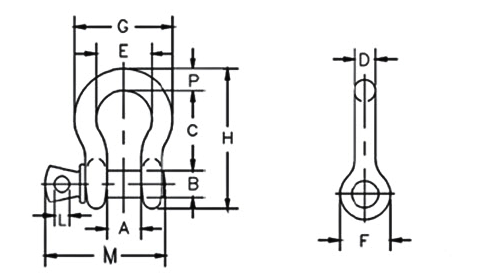

Dimensions (IN.)

TOLERANCE

(+ / -)

A

B

C

D

E

F

G

H

L

M

P

C

A

3/8

2

G209A3/8CS-5P

1017450

0.31

0.66

0.44

1.44

0.38

1.03

0.91

1.78

2.49

0.25

2.03

0.38

0.13

0.06

7/16

2-2/3

G209A7/16CS-5P

1017472

0.38

0.75

0.50

1.69

0.44

1.16

1.06

2.03

2.91

0.31

2.38

0.44

0.13

0.06

1/2

3-1/3

G209A1/2CS-5P

1017494

0.63

0.81

0.63

1.88

0.50

1.31

1.19

2.31

3.28

0.38

2.69

0.50

0.13

0.06

5/8

5

G209A5/8CS-5P

1017516

1.38

1.06

0.75

2.38

0.63

1.69

1.50

2.94

4.19

0.44

3.34

0.69

0.13

0.06

3/4

7

G209A3/4CS-5P

1017538

2.35

1.25

0.88

2.81

0.75

2.00

1.81

3.50

4.97

0.50

3.97

0.81

0.25

0.06

7/8

9-1/2

G209A7/8CS-5P

1017560

3.61

1.44

1.00

3.31

0.88

2.28

2.09

4.03

5.83

0.50

4.50

0.97

0.25

0.06

1

12-1/2

G209A1CS-5P

1017582

5.32

1.69

1.13

3.75

1.00

2.69

2.38

4.69

6.56

0.56

5.07

1.06

0.25

0.06

1-1/8

15

G209A11/8CS-5P

1017604

7.25

1.81

1.25

4.25

1.16

2.91

2.69

5.16

7.47

0.63

5.59

1.25

0.25

0.06

1-1/4

18

G209A11/4CS-5P

1017626

9.88

2.03

1.38

4.69

1.29

3.25

3.00

5.75

8.25

0.69

6.16

1.38

0.25

0.06

1-3/8

21

G209A13/8CS-5P

1017648

13.25

2.25

1.50

5.25

1.42

3.63

3.31

6.38

9.16

0.75

6.84

1.50

0.25

0.13

* Maximum Proof Load is 2 times the Working Load Limit. Minimum Ultimate Strength is 4.5 times the Working Load Limit. For Working Load Limit reduction due to side

loading applications